PPC 250 R6

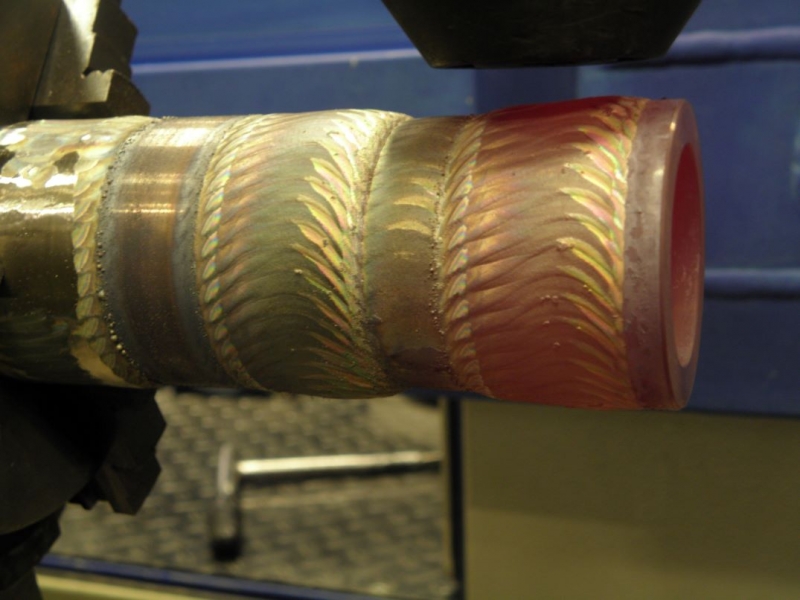

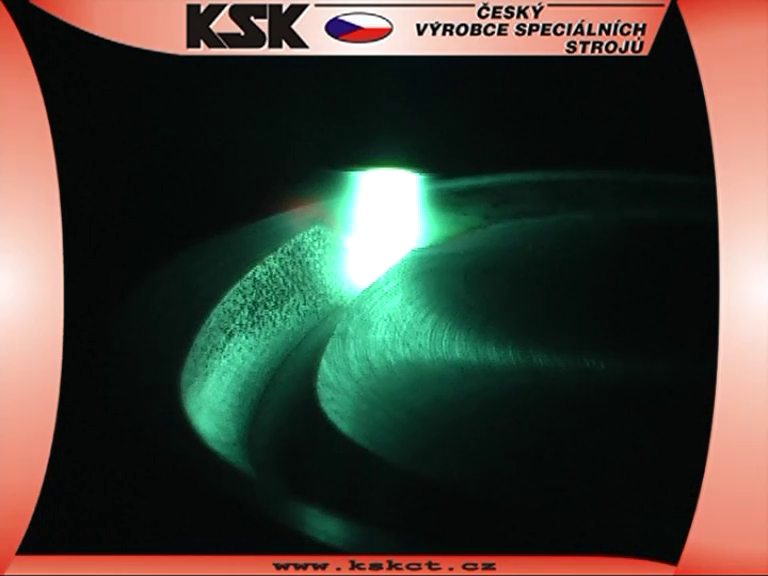

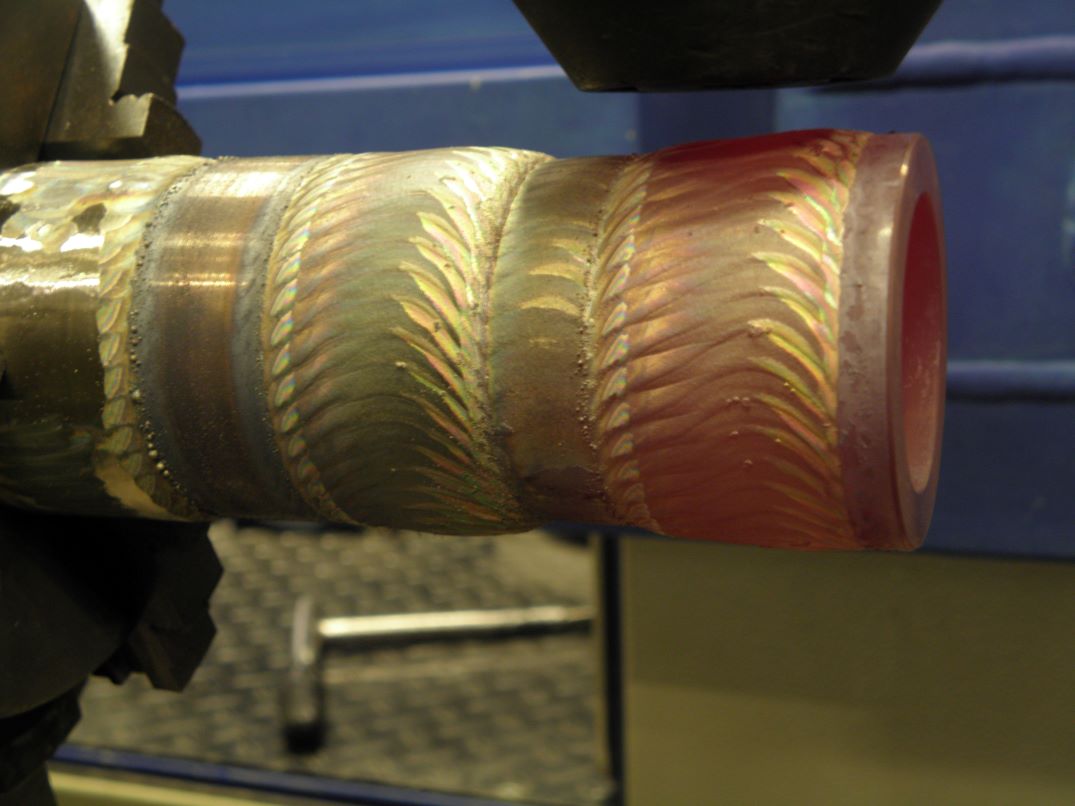

Plasma weld surfacing automate PPC 250 R6 serves for weld surfacing of rotary parts from face or onto the circuit (seats, wedges and cones of armatures, centring rings, mouth molds, bottoms and closing heads of glass moulds, valves and seats of combustion engines, etc.) by PTA method with powder.

+ positioning system of the torch, controlled in 4 axes X, Y, Z, N

+ positioner of surfaced part controlled in 2 axes C, R

+ table diameter 300 mm

+ table carrying capacity max 70 kg

+ manual mode with parameters recorded into the programme

+ programmable weld surfacing cycle

+ programming in dialog PPC or by “Tech-in” method

Basic information KSK, s.r.o.

KSK s.r.o. was established in 1991 as a private Czech company specialised in custom-made construction and production of special and single-purpose machines and devices. Its aim is to meet the complete range of our customers’ needs from the selection or development of suitable technology to the construction and production of a machine. Training of servicing staff, technical support and service throughout the machine life-time are a matter of course. KSK s.r.o. is also involved in other business activities, for instance the sale of auxiliary materials for welding, mechanical water filters, etc.

WHAT WE DO

- + construction and production of machines for welding and surfacing

- + technical and consulting services for technological processes of welding and surfacing

- + technical and consulting services for the selection of auxiliary materials

- + sale of welding materials of the voestalpine Böhler Welding, ALUNOX GmbH, ESAB, DEW

- + renovation of worn-out parts

- + co-operation with welding and surfacing

- + construction and production of testing benches

- + repair, overhaul and modernization of machines, including electrical, hydraulic and pneumatic ones

- + production and sale of filters for mechanical impurities

Copyright © 2025, KSK, Ltd All Rights Reserved. | Created by OMEGA WEB Czech, OMEGA Czech