Firma KSK s.r.o. vznikla v roce 1991 jako soukromá ryze česká firma se zaměřením na zakázkovou konstrukci a výrobu speciálních a jednoúčelových strojů a zařízení. Její náplní je komplexní uspokojení potřeb zákazníka od vytipování nebo vývoje vhodné technologie, až po zkonstruování a vyrobení stroje. Samozřejmostí je zaškolení obsluhy, technická podpora a servis po dobu životnosti stroje. KSK s.r.o. se zabývá rovněž obchodní činností, například prodejem přídavných materiálů pro svařování, mechanických filtrů na vodu apod.

Naše aktivity:

-

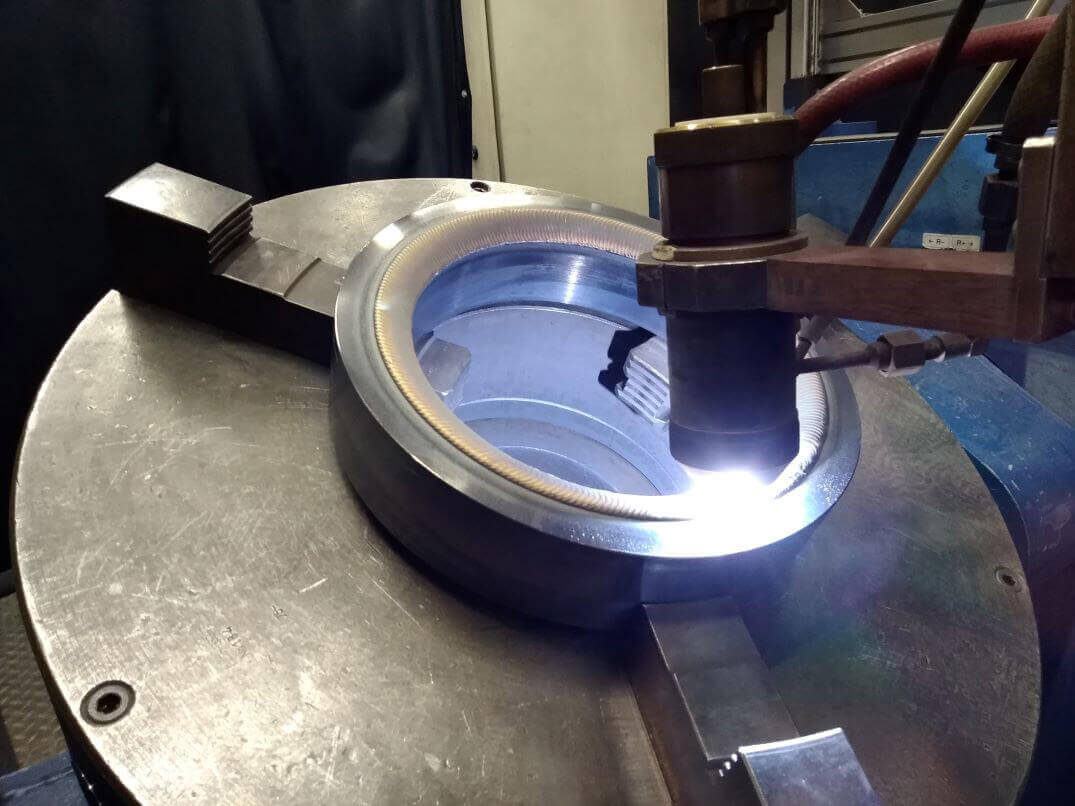

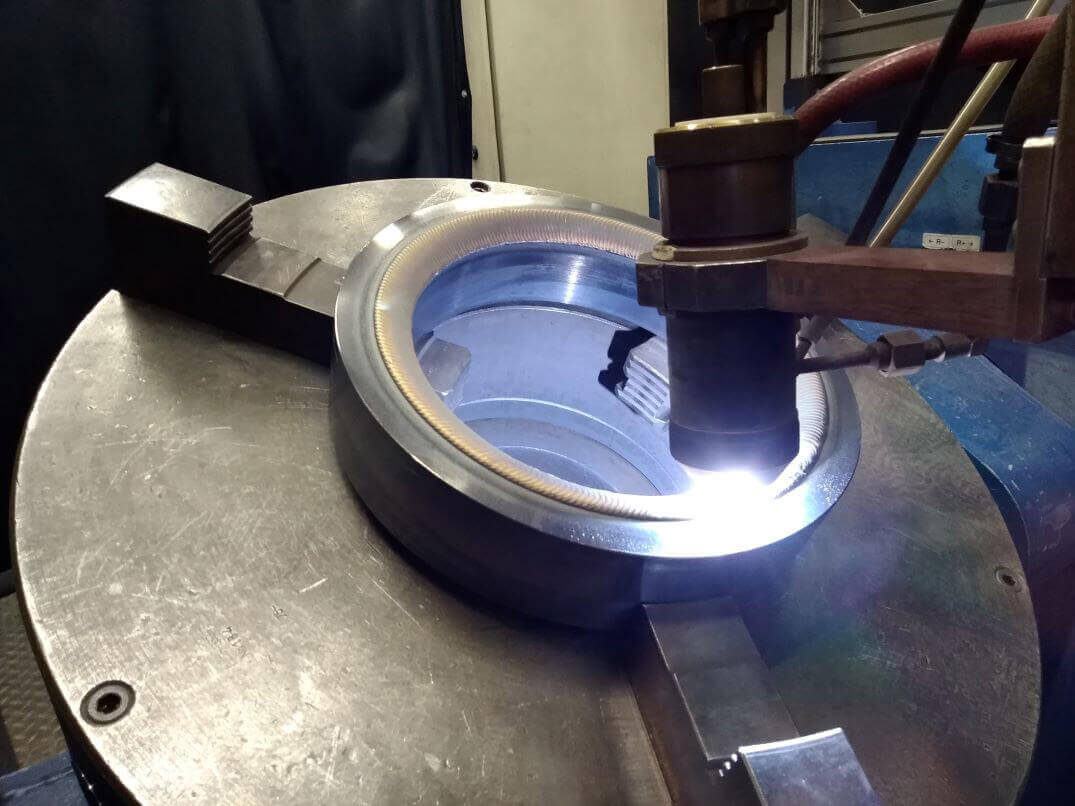

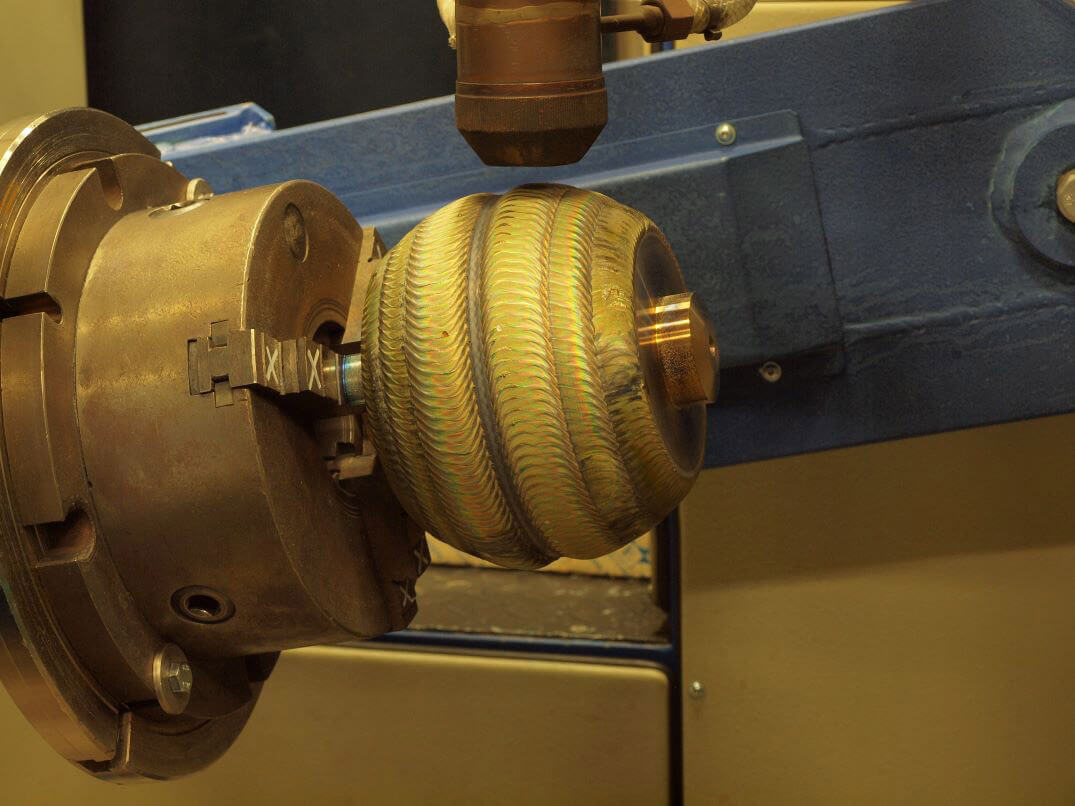

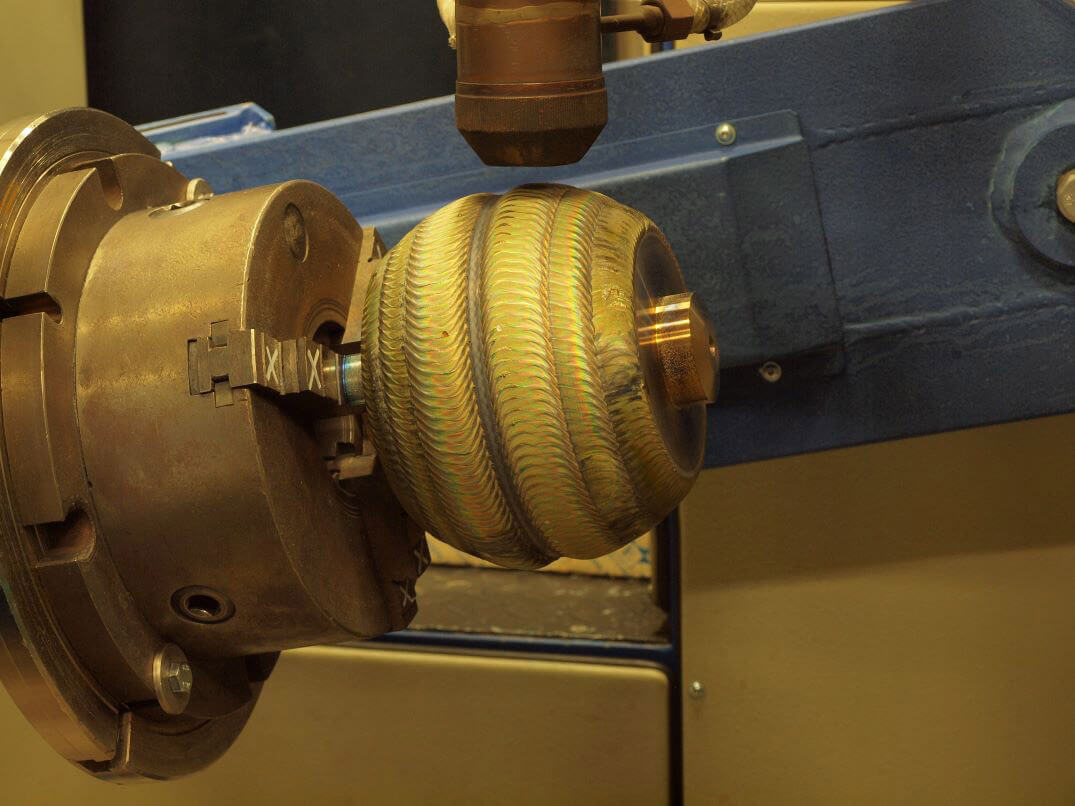

konstrukce a výroba strojů pro svařování a navařování

-

technické poradadenství pro technologické procesy svařování a navařování

-

technické poradadenství pro vytipování přídavných svařovacích materiálů

-

prodej svařovacích materiálů voestalpine Böhler Welding, ALUNOX Schweißtechnik, ESAB, DEW

-

renovace opotřebovaných součástí

-

kooperace při svařování a navařování

-

konstrukce a výroba zkušebních stolic

-

opravy, repase a modernizace strojů, včetně elektrických, hydraulických a pneumatických okruhů

-

výrobu a prodej filtrů na mechanické nečistoty

Naše aktuální certifikáty ISO 9001: 2015 najdete v kategorii "ke stažení"

https://www.kskct.cz/cs/ke-stazeni

.jpg)

.jpg)